Pharmaceutical machinery manufacturing is evolving rapidly, driven by new technologies and market demands. At Lodha International LLP, we are deeply involved in these changes, continuously adopting the latest trends to deliver high-quality solutions. Staying current with these advancements is key to meeting the growing needs of pharmaceutical companies worldwide. From automation to sustainability, these trends are transforming how pharmaceutical products are made, allowing manufacturers to be more efficient and adaptable. By integrating these developments, Lodha International LLP improves productivity and helps businesses maintain compliance with industry regulations.

Our approach at Lodha International LLP focuses on merging the latest technology with practical, user-friendly machinery. As the pharmaceutical landscape shifts, we make sure our solutions are ready to meet the unique challenges that come with modern production. This flexibility allows us to work with a wide range of clients, helping them achieve faster, safer, and more efficient operations. Whether it’s small batch production for personalized medicine or large-scale manufacturing, we provide customised equipment to fit specific needs.

Working with Lodha International LLP means you are partnering with a company that values innovation and performance. We remain committed to keeping up with the newest trends in pharmaceutical machinery, offering solutions that can adapt to the evolving needs of the industry. Our focus on quality, performance, and efficiency makes sure that our clients stay competitive in an ever-changing market. With Lodha, you gain more than just machinery – you gain a trusted partner invested in the success of your business.

In pharmaceutical manufacturing, standardization plays a critical role in improving both efficiency and product quality. At Lodha International LLP, we adhere to industry norms and guidelines that streamline the design, production, and operation of our machinery. This focus on standardized processes helps reduce errors, improve safety, and make the production line more effective. By following global regulatory standards such as ISO 9001:2015 and cGMP, our machines deliver consistent results, making it easier for businesses to achieve high productivity while maintaining the quality of their products.

Automation is one of the most impactful trends in pharmaceutical machinery today. At Lodha International LLP, we integrate the latest automation technologies, including robotics, and machine learning, into our machinery. These advancements help speed up production, increase accuracy, and reduce human errors. Automation also improves the efficiency of repetitive tasks, allowing manufacturers to focus on more complex processes. Our automated solutions are designed to be flexible, enabling businesses to quickly adapt to changing market demands while maintaining a high level of productivity.

As the demand for precision medicine grows, the pharmaceutical industry is moving towards flexible production systems. Lodha International LLP leads this shift by offering machinery that allows manufacturers to easily switch between different production lines. This adaptability is key for producing smaller, personalized batches without sacrificing efficiency. Our flexible production solutions enable companies to meet the needs of modern healthcare, from mass-producing standard medications to developing customized therapies. With our machines, businesses can efficiently manage their production while staying responsive to the evolving pharmaceutical landscape.

Continuous manufacturing is changing the game in the pharmaceutical industry. Unlike traditional batch manufacturing, which produces set quantities at specific times, continuous manufacturing allows for a steady flow of materials and products. This method not only improves consistency but also boosts efficiency by reducing waste and increasing yields. Companies can monitor the process in real time, adjusting as needed to meet strict quality standards. Lodha International LLP is leading the way in this transformation with advanced machinery that supports this modern approach. By adopting continuous manufacturing, pharmaceutical manufacturers can better meet market demands while focusing on quality and efficiency. It’s not just a trend; it’s a smart move towards a more sustainable and profitable future in the industry.

Single-use bioreactors are becoming a popular solution in pharmaceutical manufacturing due to their ability to cut downtime and increase efficiency. At Lodha International LLP, we incorporate single-use technology into our product offerings, allowing manufacturers to reduce cross-contamination risks and minimize cleaning efforts. These bioreactors are ideal for companies looking to streamline their production process while maintaining high safety and quality standards. By opting for single-use bioreactors, manufacturers can lower operational costs and boost their overall productivity, making them a smart choice for modern pharmaceutical production.

The shift towards green manufacturing is reshaping the pharmaceutical industry, and Lodha International LLP is at the forefront of this movement. We design machinery that focuses on reducing waste, energy usage, and carbon emissions. By adopting eco-friendly practices, we help businesses lower their environmental footprint while still achieving high levels of production. Our energy-efficient machines not only support sustainability but also reduce operating costs, making green manufacturing a win-win solution for both businesses and the environment. As the industry continues to evolve, adopting sustainable practices will be important for long-term success.

Efficiency is key in the pharmaceutical manufacturing industry, and Lodha International LLP is dedicated to helping businesses maximize their productivity. Our machinery is designed to operate at high speeds, with greater production capacity and longer operational hours. This helps businesses produce more in less time while maintaining the highest quality standards. Whether you need equipment for large-scale production or specialized machinery for smaller batches, our machines are built to deliver maximum efficiency. By investing in our solutions, businesses can reduce downtime, lower operational costs, and increase their output, making them more competitive in the market.

At Lodha International LLP, we are committed to providing the best solutions in pharmaceutical machinery manufacturing. By staying up to date with the latest trends and technologies, we offer products that are not only innovative but also reliable and efficient. As an ISO 9001:2015 certified company, we adhere to the highest standards of quality and regulatory compliance. Our machines are built using premium components, making sure long-term durability and performance. We also offer complete after-sales service, providing easy access to replacement parts and support whenever needed. Choosing Lodha means working with a partner who is dedicated to your business's success.

Lodha International LLP is proud to lead the way in pharmaceutical machinery manufacturing by incorporating the latest trends into our products. From automation and green manufacturing to single-use bioreactors and starchless depositing, we provide solutions that help businesses meet the demands of an evolving industry. By choosing Lodha, you’re not just investing in high-quality machinery – you’re partnering with a company that is committed to innovation, quality, and your long-term success. Our dedication to excellence confirms that our clients are always equipped with the best tools to thrive in the competitive pharmaceutical market.

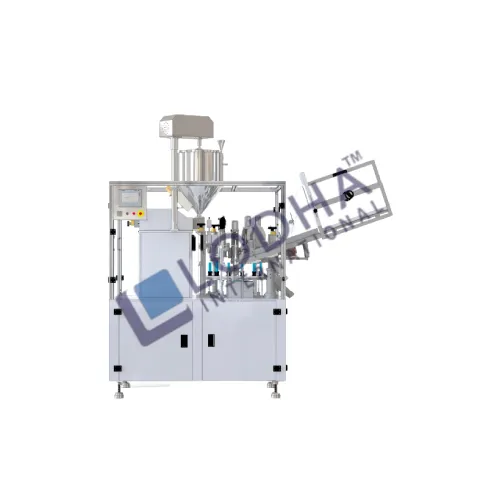

Our company offers complete packaging lines and processing equipment used in the production, quality control and formulation labs of pharmaceutical, dietary supplements, food, cosmetic and chemical industries. We offer a full range from production scale to small batch manufacturing equipment ideal for liquids, injectables, tablets, capsules, powders, creams and ointments.

Explore