Capsule line machines are essential in the pharmaceutical industry for producing capsules, which are a common form of medication. These machines are highly sought after due to their efficiency and capability in handling capsules and tablets. The various types of capsule line equipment include capsule polishing machines, capsule printing machines, capsule inspection machines, capsule counting machines, capsule filling machines, capsule loaders, and combined capsule counting and filling machines.

Lodha, we specialize in manufacturing and exporting high-speed capsule filling machines for the pharmaceutical sector. Our automatic machines can fill hard gelatin capsules with powders, pellets, tablets, and granules with high precision and efficiency. Depending on the model, these machines can produce up to 150,000 capsules per hour, making them ideal for large-scale production in the pharmaceutical, nutraceutical, and herbal industries. Constructed from stainless steel 316, these machines are cGMP compliant, ensuring top standards of hygiene and durability. They are designed to operate smoothly and quietly with minimal maintenance and can handle capsule sizes 00, 0, 1, 2, 3, 4, and 5. Advanced electrical components and PLC systems improve the quality and precision of the filling process.

Lodha also offers fully automatic capsule filling machines that are engineered for the pharmaceutical industry. These machines can fill hard gelatin capsules with powders, pellets, tablets, and granules accurately and efficiently. Advanced production technologies allow for precise filling of various materials, and the efficient tamping mechanism enables quick adjustments to fill weight, boosting productivity.

Our double loader semi-automatic capsule filling machines are designed for the pharmaceutical, nutraceutical, and herbal sectors. These machines efficiently fill hard gelatin capsules with powders, pellets, tablets, and granular materials. They accommodate all capsule sizes and types, featuring HMI and PLC systems for easy, touch-screen automation and precise control. Built from high-quality stainless steel, our machines are GMP-compliant and meet the highest industry standards for quality and safety.

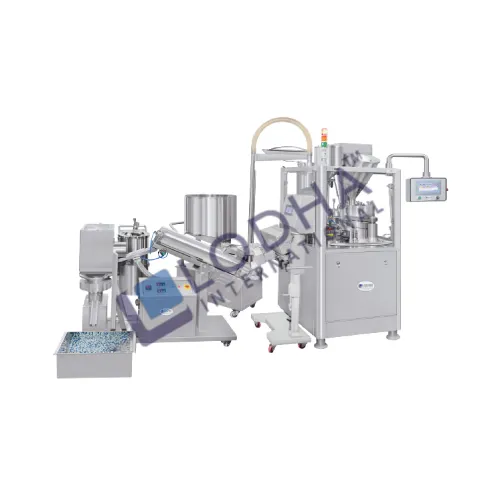

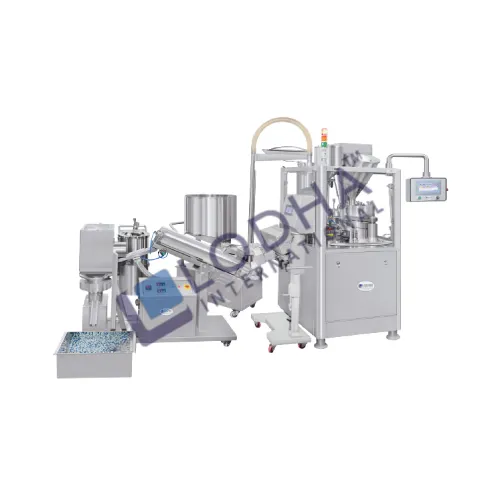

Capsule counting and filling machines are used to count and fill capsules into bottles, jars, bags, and pouches. These machines work with both plastic and glass bottles and are commonly used in the pharmaceutical, nutraceutical, cosmetic, herbal, and ayurvedic industries for small-scale production. The GMP-standard design makes sure high quality, while the stainless-steel frame confirms durability. Custom-made discs are adjusted to fit each customer's specific filling needs. We also offer electronic capsule counting machines with PLC-based systems that automatically sense and count capsules, providing precise and efficient filling.

The capsule polishing machine, or capsule polisher, cleans the capsules by removing powder particles from their surfaces. It features a polishing chamber with a rotating spiral brush that effectively removes sticky particles. Attached to a vacuum cleaner, it sucks up the de-dusted powder, improving polishing quality. The adjustable angle of the polishing chamber allows for able use without needing part changes to handle different capsule sizes.

Our empty capsule sorter machines are designed to meet the specific needs of various industries, including cosmetics, pesticides, biotech, herbal, and nutraceutical sectors. These machines improve capsule quality by separating and rejecting empty or damaged capsules, ensuring only the best capsules proceed to the next production stage. User-friendly and capable of handling various capsule sizes without changes, these machines save floor space with their compact design. Built from high-quality stainless steel, they are durable and meet industry standards. Maintenance is simple, with easy disassembly for cleaning and routine upkeep, ensuring minimal downtime.

Lodha also manufactures dust extractor machines designed to meet the varies needs of various industries. These machines are essential for collecting loose powder from the polishing chamber, resulting in a cleaner workspace and improved production efficiency. They are important for the proper operation of capsule polishing machines, effectively removing excess powder that accumulates during the polishing process.

Lodha offers a comprehensive range of high-quality capsule line machines designed to meet the demanding requirements of the pharmaceutical, nutraceutical, and herbal industries. Our machines are efficient, precise, and hygienic production, improving the quality of the final product while maintaining compliance with industry standards.

Our company offers complete packaging lines and processing equipment used in the production, quality control and formulation labs of pharmaceutical, dietary supplements, food, cosmetic and chemical industries. We offer a full range from production scale to small batch manufacturing equipment ideal for liquids, injectables, tablets, capsules, powders, creams and ointments.

Explore