A tube-filling machine is designed to fill up and seal tubes with different products that may include creams, gels, ointments, and pastes. The pharmaceuticals, cosmetics, food, and chemical industries show large interest in these machines, in which great performance must be taken care of in hygiene aspects. A tube filling machine basically automates the operations that involve the filling and sealing of tubes, confirming good consistency in product packaging. These machines are designed to manage a variety of tube materials, including plastic, aluminum, and laminate; thus, they are capable tools within the manufacturing arena. Automation in filling will help a company to speed up production without compromising product wastage or quality. Tube-filling machines are particularly important in areas where the integrity of the packaging directly influences the effectiveness of the product, such as in pharmaceuticals and cosmetics.

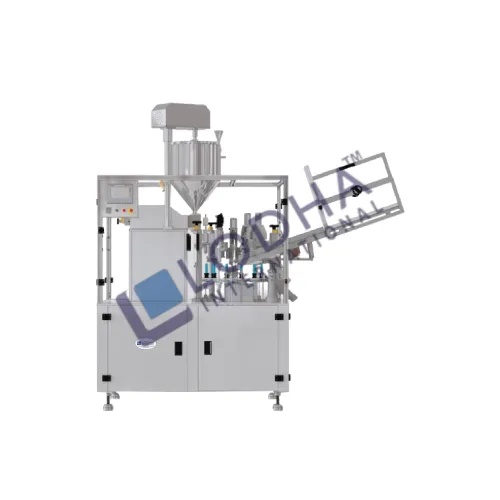

Lodha International LLP is one of the leading manufacturers and exporters of pharmaceutical machinery. The company provides technically advanced tube filling machines, which can also be fabricated according to customer needs in varies industries. These machines are fabricated with advanced technology options for single- and double-head filling, thus allowing the manufacturer to choose appropriate equipment that fits the requirements of their production. It is worth noting that if single-head machines fill 30 to 40 tubes at one time, a double-head machine fills 60-70 tubes, increasing the rate of production enormously. These machines are also manufactured with SS cladding-that is, a chemical coating to make them more durable and resistant to wear and tear for reliable performance over a long period of time. With quality and an innovative approach, Lodha International LLP's tube-filling machines have made it to one of the first choices of any firm with a view to smoothening its production process.

Lodha International LLP deals in various types of tube filling machines according to their use in different industrial requirements. Essentially, there are two types of tube filling machines, namely Plastic Tube Filling Machine and Aluminium Tube Filling Machine.

The Plastic Tube Filling Machine is fabricated and designed to operate with plastic tubes of varied sizes. It operates on a rotating disc system; hence, it allows easy changeability of its tube holder for adjustments of the tube sizes. The machine would, therefore, be very efficient for manufacturers operating with numerous product lines in that with this machine, one can easily switch between tube dimensions without necessarily losing efficiency. It has a well-structured machine that accurately fills each tube and tightly seals it, thus making the machine very suitable for industries dealing in cosmetics, pharmaceuticals, and food, where consistency and hygiene of the product are paramount.

The Aluminium Tube Filling Machine is designed to be simple yet strong. Basically, it operates similarly to a rotating disc system of the plastic tube filling machine but is designed for handling aluminum tubes. This machine enjoys changeable tube sockets that make it convenient for many sizes of tubes. Its simple design makes sure ease of use, and its strong construction assures longevity even in high-demanding production conditions. It has wide applications in various industries concerning filling into metal tubes, such as adhesives, paints, and specific pharmaceuticals. Lodha International LLP's aluminium tube-filling machines offer workable and effective solutions for those companies that would like to stand by their high production standards.

A tube filler works on the principle of automation and precision. Essentially, the process initiates by inserting the tubes into tube holders within a machine; this is done either automatically or manually by hand, depending on the model. With the tubes put in, the holders rotate with a rotary table, conducting the tubes through various workstations. Each workstation has some different kind of responsibility: filling the tube, sealing it, or applying a code or label. They are pre-programmed functions commanded by the machine control unit to make sure each step follows in due order.

The machine, therefore, executes each task with performance as the tubes pass through the workstation for consistent filling and sealing. Some of the salient features of the tube-filling machines manufactured by Lodha International LLP include adjustability of filling quantity and speed to suit individual requirements of every production run. This allows a wide range of products to be manufactured on the same machine, improving flexibility and efficiency in the production process. This whole operation minimizes the generation of waste and maximizes output; hence, the tube filling machine becomes an important constituent in modern manufacturing facilities.

Tube filling machines play an important role in many industries because of their capability and efficiency. They find wide applications in the packaging of various products with the certainty that the packaged products are consistent and reliable. Following are the major applications of the tube filling machines:

Tube filling machines are a very significant way of effectively packaging products in various industries, including pharmaceuticals and cosmetics. These machines confirm performance in product filling and sealing, and at the same time, Provide high levels of quality and hygiene in the process. The range of tube filling equipment from Lodha includes means to suit various client requirements. Features include advanced features like adjustable filling quantity and speeds. From plastic to aluminum tubes, we avail you with the quality and efficiency for durability to serve your production needs best. Whether it is plastic or aluminum tubes, Lodha International LLP is committed to innovation and quality, hence a better partner for businesses in packaging optimization.

Our company offers complete packaging lines and processing equipment used in the production, quality control and formulation labs of pharmaceutical, dietary supplements, food, cosmetic and chemical industries. We offer a full range from production scale to small batch manufacturing equipment ideal for liquids, injectables, tablets, capsules, powders, creams and ointments.

Explore